Quality

TECNOFOR QUALITY STANDARDS

Quality Control and Assurance

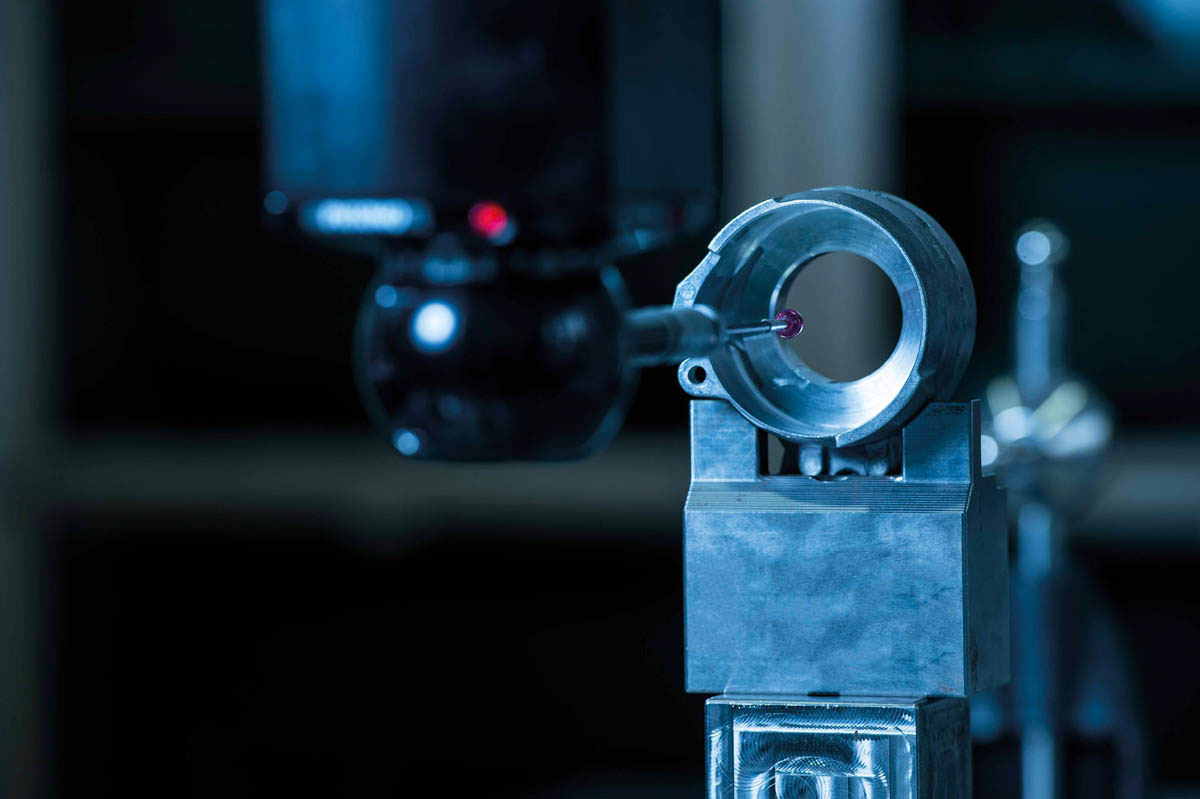

The production of all of the parts that the group manufactures is monitored by a systematic process inspection: the measuring equipment onboard the machines and the continuous supervision of Quality Control and Assurance personnel make it possible to guarantee a high standard of production.

Every stage in the production cycle is documented by quality control personnel, which is why it is easy to guarantee a batch’s traceability.